You have been exposed to twill fabric when you put on a pair of jeans, a good trench coat or a work uniform. It is easily identified by the trademark diagonal lines, or twill weave, a characteristic which makes the cloth incredibly strong and able to be used in many ways. The interlacing of the yarns also affects the performance of the fabric.

This gives twill the right to have its own strength, as well as smooth and non-slippery gather, and the capability of withstanding daily use and destruction, which is a major gain in the context of sustainability. Continue reading to know how the special weave of twill can help it achieve its performance and fashionable appearance.

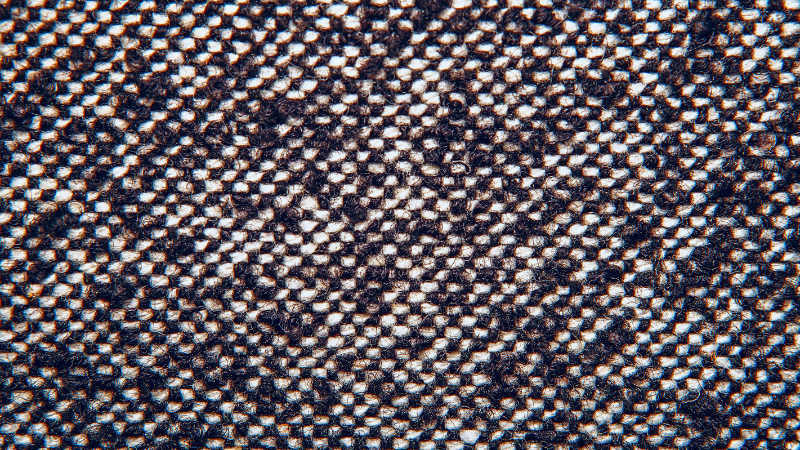

What Is a Twill Weave?

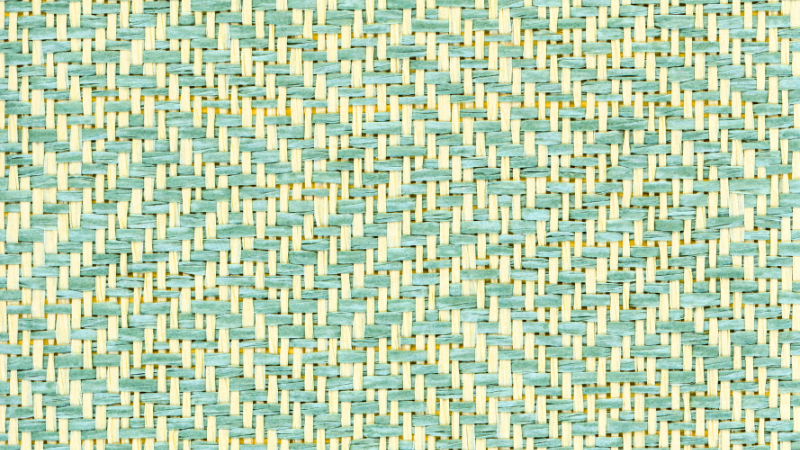

One of the three basic weave types used in the textile industry is the twill weave which has a characteristic diagonal rib or wale design that provides the textile with depth as well as strength. This is made possible by a particular interlacing technique where the weft yarn (horizontal thread) crosses and under one or more warp yarns (vertical threads) in a randomized manner in each subsequent row by one thread.

The result is a continuous diagonal construction, and this can be varied in terms of angle and eminence with the number of yarns passed or crossed in the weave. Not only does this construction add aesthetic value to the fabric, but it also makes the fabric more durable, flexible, resistant to wrinkles and soil. In addition to adding strength and comfort to the garments, it is used in denim, chinos, and workwear and in upholstery and home textiles.

The Mechanics of the Diagonal Rib

The twill weave has a float system, as opposed to the plain weave, which has a one-over, one-under interlacing. This cross-over part, which extends across some yards in the opposite way, and crosses again, is known as a float.

- Interlacing Points/ Ratios: Interlacing refers to a twill weave whose pattern is repetitive. The numerator (Numbers 2 or 3) indicates the number of warp yards that the weft floats around. The denominator (1) indicates the number of warp yards on which it passes. This is a fraction ratio in which the weave is defined. An example of this is a 3/1 twill, which is applied in long-lasting denim, with an underlay being the weft, and then overlaid on three warp yards and then underlaid on one.

- The Stagger: The next roll of weft begins to interlock at a single step towards the right-hand side. This constant motion ensures the twill weave pattern is not disturbed by the surface of the sturdy table fabric.

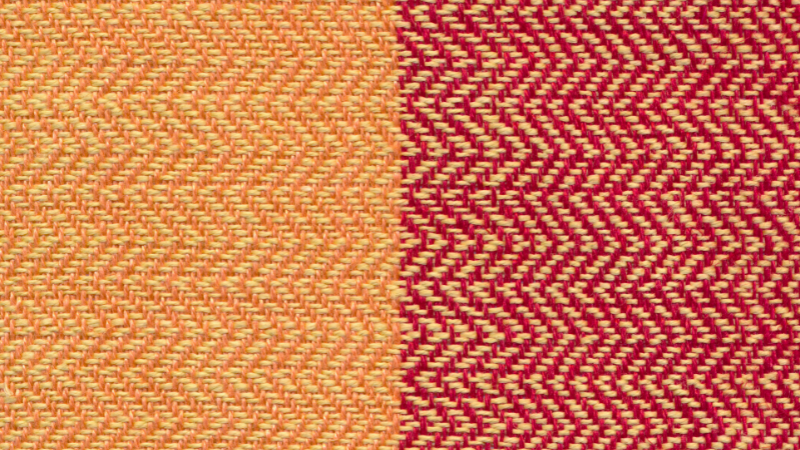

Twill Direction: Right-Hand vs. Left-Hand

The angle of the diagonal line has an effect on the hand-feeling and appearance of the twill fabric.

- Right-Hand Twill (Z-Twill): The diagonal is right and upwards, which is equivalent to a letter Z. This twill is the most prevalent and is mostly used in traditional denim. It is more compact and is a bit coarser.

- Left-Hand Twill (S-Twill): The diagonal line is going up and to the left and is therefore parallel to a letter S. Left-hand twills tend to feel softer and also do not twist or skew after washing, much better than right-hand twills.

Twill vs. Plain Weave: The Structural Difference

The primary difference between twill and plain weave is the number of interlacing threads. The highest number of interlacing points occurs in a plain weave. This gives it a sharp, hard, flat texture.

On the contrary, the interlacing points and length of floats are fewer in a twill weave, which allows the threads to fit together more closely. This enhances the density and elasticity of the fabric. Upon comparison of the two, you will find that twill is more solid and firm.

Key Properties of Twill Fabrics

Twill weaves have many desirable properties that are attributed to the unique construction. This renders it a popular choice of practical and quality garments.

- Durability and strength: The interweaving is more dense than other weaves, which means that more yard is packed in each square inch. This renders twill fabrics very tough and durable. The twill materials with 3/1 proportion lessen the wear points, making the tension even. This enhances life and longevity.

- Different diagonal lines and texture: This texture contributes to the depth of movement. It assists the fabric to cover the slight creasing and imperfections of the fabric more efficiently than a plain straight weave. The ribs form a slight loft, resulting in softness.

- Good drape and flexibility: The yards are not interlaced with such frequency. This enables the twill material to be less stiff and more flexible. It also hangs much better than a stiff plain weave of the same fiber content.

- Wrinkle and stain resistance: Minor soiling is not visible on the surface, which is very high in hiding wrinkles. The diagonal construction aids in the easy shedding of dirt and liquid. It reduces the proportion of stains.

- Resilience and recovery: The twill fabrics are easy to stretch or crumple and they recover. This is a very important property in clothing such as pants. The garment maintains its shape and does not bag out at the knees or the seat.

- Opacity, weight and fiber blends: The dense structure and high thread count gives the fabric a very high level of opacity. This suits it best with outer things, pants and skirts. This density adds to its increased total weights. You are offered twill made of cotton, polyester or even a cotton polyester mix, which may contain spandex to stretch. You put twill on virtually anything to final use.

Common Types of Twill Weave Fabrics

Some of the most widespread and ancient types of twill fabric in the apparel industry are based on the twill weave structure.

- Denim: Denim is the standard of twill textile strength. It is a coarse cotton twill, which is usually a 3/1 right-hand weave, in which the dye is applied on the warp threads (usually blue indigo), and the weft is left white. Denim is the jacket of jeans and casual jackets because of its structural integrity.

- Chino: It is a finer, lighter twill with cotton. Casual trousers and summer jackets are some of the items we use it on. Chino is made of finer yard as compared to denim and therefore it is smoother in hand and has a less prominent diagonal rib. Chinos are comfortable and durable to wear on a daily basis.

- Gabardine: It is a close-woven, strong twill which has a steep and sharp diagonal rib. It utilizes close-set, fine yardage, sometimes with the worst, cotton polyester blends. Its narrow design is wind and rain resistant. Gabardine is the traditional material to use in high-end suiting, uniform trousers and classic trench coats.

- Drill: This is a heavy, strong cotton twill fabric that is heavier and coarser than denim. It is very strong and is mostly utilized in the heavy workwear, heavy uniforms, canvas-like uses and upholstery.

- Serge: Serge is a traditional twill which is normally manufactured using wool or mixed fibers. It is fine, smooth and diagonal. Serge is used in suits, military uniforms and coats because it does not wrinkle, creases neatly, and folds beautifully.

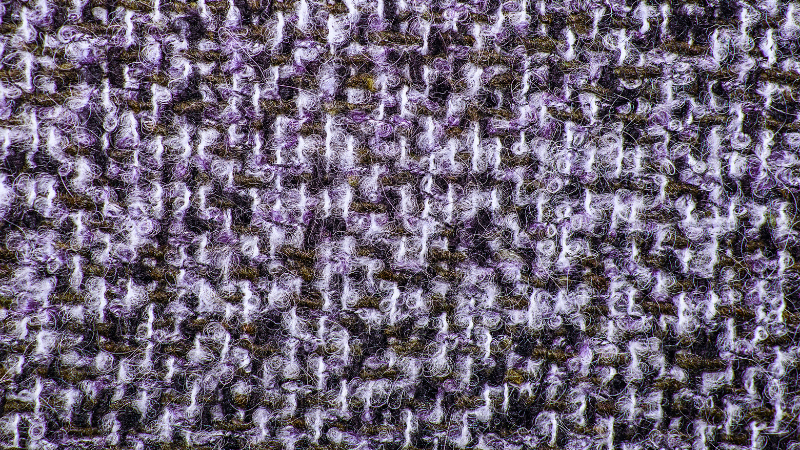

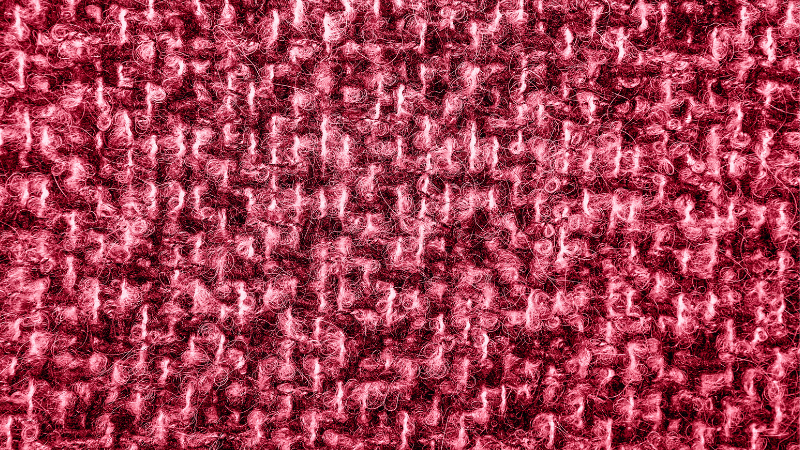

- Herringbone Twill: It is a decoration form of twill weave. The diagonal movement changes direction periodically in a zigzag or a chevron style. We apply this reversing technique frequently in tweed jackets and expensive suiting to give the piece a texture.

- Houndstooth: This is a form of decorative twill that forms a checked design that is broken. It is also very prized as accessories, coats and blazers.

Advanced Twill Variations and Design

Variations are used to control the texture, pattern and performance of the fabric by designers and textile engineers.

- Broken Twill: This is a variation which discontinues the diagonal line. It makes the cloth look more haphazard or rough and does not make the twill weaker. We also apply it frequently to avoid the skewing or spiraling which occasionally occurs in continuous twill weaving.

- Basket Weave Twill: This is a twill interlacing design, only that two or more yards of warp are bound up together. It interlaces the group in a form of a unit when interweaving with the weft. This gives a more relevant, almost 3-dimensional texture.

- Cavalry Twill: It is known since it is rough. It has steep and raised diagonals which are observable and proximate to each other. Each twill provides an unbelievable toughness. We are wearing it now in heavy coats and fancy trousers.

- Warp-Faced vs. Weft-Faced: The Majority of twills such as denim are warp based. The surface has a greater number of warp yards than weft yard. Welt twills are available, but not so common. They put emphasis on the horizontal yard on the surface.

Twill Weave Strength and Weaknesses

Before deciding on twill weave, you have to consider the obvious advantages and disadvantages of its use.

Advantages

- Excellent longevity and Durability: Twill fabric has a high thread count and packed structure, hence making it very resistant to tears, abrasion and pilling. This is a practical advantage that increases the life of the garment.

- Great Drape and Soft Hand: Longer floats enable the fabric to be smoother and have a soft bend. This eliminates the looseness of certain tight woven plain weaves. It produces more comfortable clothes.

- High Density and Weight: Twill is non-transparent. It is dense enough to keep out the wind and cold. Its density makes it convenient to a lot of items.

Disadvantages

- Heavier than Plain Weaves: The tighter the yards are filled, the heavier is the twill than a plain weave out of the same material. This restricts its application in lightweight summer clothes.

- A little more expensive to make: The complicated staggering of the yards demands complicated looms and low weaving rates. This elevates the cost of production.

- Risk of skewing: The yards roll in a single main direction, which is in a diagonal direction. This occasionally makes continuous twill fabrics to twist or skew after washing. You overpower this by good cutting and finishing.

Common Applications of Twill Fabrics

The longevity of the twill fabric and its beauty imply that its twill fabric applications are wide spread in numerous industries.

- Heavy-Duty Apparel: The basic base of everyday wear and working hard clothes is twill. You will find it in casual attire (jeans, jackets) to trousers and shorts. It is strong enough that it is ideal for clothes that are subjected to daily stress. Stretch pants would be perfect with cotton twill with a hint of spandex.

- Formal and Outerwear: Excellent twills like the gabardine and serge fabrics are worn in tailored suits, in blazers and professional coats. The twill design assists the fabric to have a crisp, sharp crease, which is necessary in formal clothes.

- Home Textiles: Twill wrinkle and stain resistance can find application in domestic fabrics such as upholstery fabrics, curtains, and cushions. It possesses an organized look quite well.

- Protective and Industrial Use: Heavy twills such as drill and canvas are used in the protection of outer clothing, heavy use utility bags, and specialty work wear. They have better resistance to abrasion as compared to other fabrics.

Twill vs. Plain Weave: Key Differences

This comparison can be used to identify the properties that will match your design requirements when choosing a fabric.

| Feature | Twill Weave | Plain Weave |

|---|---|---|

| Structure | Staggered float, diagonally shaped ribs (wale). | Smooth, flat and regular (checkerboard) interlacing. |

| Strength | More resilient, High density. | Middle, less resistant to tears. |

| Drape | Softer, flexible, fluid hand | Crisper, often stiffer hand |

| Wrinkle Resistance | Thick (creases in diagonal hides) | Reducing (reductions are very noticeable) |

| Fiber Requirement | Strikes best on high yards (e.g. ring-spun cotton) | Supports a greater variety of types of yards. |

| Common Uses | Workwear, jeans, jackets, chinos. | Shirts, linings, summer dresses, sheers. |

Care Tips for Twill Fabrics

Twill fabrics have a long life span when they are well maintained.

- Washing: Twill clothes should be washed in soft form. Fading is prevented by using cool water and mild detergent. Washing with garment inside out reduces the abrasion on the surface.

- Drying: Avoid over-drying. Excessive drying leads to serious shrinkage of cotton twills. To maintain the shape and feel, it is always best to dry it using air. When you have a dryer, set it to a low-heat level and take out the piece of clothing when it is damp.

- Ironing: In case you have to iron the piece of cloth, reverse the garment. This covers the face of the weave and does not allow the diagonal ribs to flatten or get shiny.

FAQ

What is twill fabric used for?

Twill fabrics fall in a wide range of categories, with durability and resilience being the most important. Its primary applications of twill fabric are heavy-duty clothing such as jeans (denim), workwear, uniforms, and comfortable casual trousers (chinos and pants). The diagonal nature of the fabric contributes to the fabric resisting additional pressure and repetitive washing as compared to plain weaves. This renders it ideal in day to day wear.

Is twill breathable?

Twill has breathable qualities that are dependent on its fiber content and weights. Lightweight chinos (such as summer twills, made of cotton) are breathable. Nevertheless, dense, bulky twills (such as dense denim or gabardine) stuff the fiber close to each other. Such density decreases air permeability.

What’s the difference between twill and denim?

Denim is a special kind of twill cloth. The diagonal weave structure, the method of construction, is called twill. The material is denim, which is a type of cotton twill. It stains the warp yards (mostly indigo) and leaves the weft yards unstained (white). As a result of this construction, denim obtains its usual blue and white shades.

Conclusion

The twill weave is a pattern that characterizes a group of textiles that are able to blend style with the durability of industrial fabrics. The diagonal structure provides strength, style and versatility whether you are sourcing heavy denim or fine gabardine to tailor your apparel.

Its special characteristics render it as one of the strongest and most stable weaves in the world textile market. You will also discover that twill is the best option when you require a fabric that can resist wrinkles, stains better, and has a premium feel.