Nylon is a synthetic polymer that revolutionized the textile industry and manufacturing industries whilst it became first added in the 1930s, yet its manufacturing moreover will increase concerns about environmental degradation .

Developed by using way of DuPont scientist Wallace Carothers, nylon became to begin with created as a silk alternative, especially for ladies’s stockings, changing many silk imports . However, its energy, sturdiness, and flexibility short made it a staple in diverse industries, from fashion to automotive manufacturing.

Unlike natural fibers along with cotton or wool, nylon is definitely man-made via a chemical method referred to as polymerization, which binds lengthy-chain molecules (polyamides) used to create a resilient and bendy fabric.

Today, nylon fabric is used inside the entirety from garb and outdoor device to commercial equipment and medical devices, showcasing its significance in the textile industry .

Key Characteristics of Nylon:

- High tensile strength – Resistant to tearing and abrasion.

- Elasticity – Stretches tough with out losing shape.

- Lightweight & easy texture – Often used in athletic wear and nylon fabric for underwear.

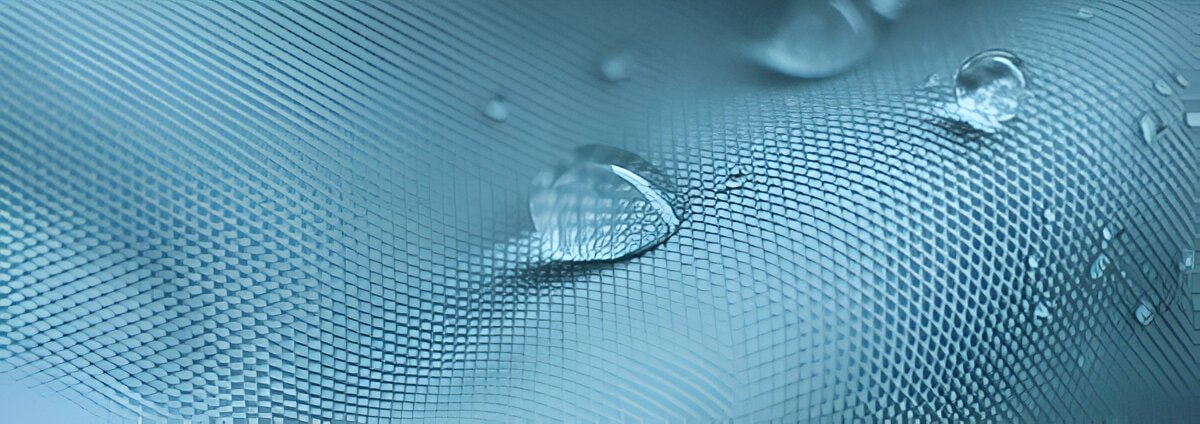

- Quick-drying & moisture-resistant – Ideal for swimwear and out of doors gadget.

- Chemical resistance – Withstands exposure to oils, solvents, and lots of acids.

Properties of Nylon

Nylon’s vast use throughout industries stems from its precise aggregate of bodily and chemical homes, which make it advanced to many herbal fibers and artificial alternatives. These traits are a direct end result of its polyamide shape, fashioned through polymerization of petroleum-based compounds, making it extensively utilized in various software . Below is an in-intensity exploration of nylon textiles and its key residences and the way they affect its performance in various programs.

Mechanical Properties

Nylon reveals notable tensile power, with some grades surpassing 12,000 psi, making it more potent than many metals by means of weight. This energy is complemented through brilliant abrasion resistance – nylon fibers can resist repeated friction with out significant put on, explaining its use in carpets and conveyor belts.

The cloth additionally demonstrates extraordinary elasticity, capable of stretching as much as 30% of its unique length before breaking, yet returning to its initial form. This combination of energy and flexibility, along with its high melting point, makes nylon hard and ideal for packages starting from climbing ropes to tents and toothbrush bristles.

Thermal Properties

With a melting factor normally between 215-265°C (419-509°F), nylon, synthesized from hexamethylene diamine, keeps structural integrity in excessive-temperature environments. This excessive melting factor, or high melting point, thermal stability allows its use in car engine components and commercial equipment components.

However, nylon’s warmness resistance comes with an crucial caveat – extended publicity to temperatures above one hundred fifty°C (302°F) can reason gradual degradation, which is influenced by its complex manufacturing process . The cloth additionally reveals low thermal conductivity, making it useful for insulating programs in electric additives.

Chemical Resistance

Nylon demonstrates terrific resistance to many chemical compounds, including oils, solvents, and alkalis, though it is able to be degraded by means of strong acids and phenols. This chemical resilience explains its giant use in gasoline lines, hydraulic hoses, and chemical processing device, as well as in nylon textiles . The fabric’s hydrophobic nature makes it naturally waterproof, even though prolonged water immersion can purpose moderate swelling (about three-9% water absorption by weight), which may additionally affect dimensional stability in precision programs.

Surface Characteristics

Nylon fibers boast a obviously clean floor that resists dirt accumulation and allows smooth cleansing. This woven smoothness, combined with the fabric’s potential to preserve vibrant dyes, makes it famous for style cloth programs. The low coefficient of friction (zero.15-0.25 against metal) permits its use in shifting components like gears and bearings without requiring additional lubrication.

Electrical Properties

As an exceptional electric insulator with excessive dielectric strength, nylon reveals packages in cord jacketing and electronic additives. Its volume resistivity commonly degrees from 10^14-10^15 ohm-cm, making it in particular valuable in electrical insulation packages wherein moisture resistance is likewise required.

These residences integrate to make nylon one of the most versatile engineering plastics available these days. However, producers often modify those characteristics thru additives or blending with other materials to optimize overall performance for precise programs, demonstrating nylon’s wonderful adaptability throughout industries.

Types of Nylon

There are several types of nylon, each with slightly different properties:

| Type | Properties | Common Uses |

|---|---|---|

| Nylon 6,6 | High strength, heat resistance | Carpets, tire cords, industrial fabrics |

| Nylon 6 | More flexible, easier to dye | Clothing, fishing nets, toothbrush bristles |

| Nylon 12 | Flexible, chemical-resistant | Fuel lines, medical tubing |

| Nylon 4,6 | High-temperature resistance | Automotive engine parts |

| Nylon 6,10 | Water-resistant, durable | Industrial brushes, electrical insulation |

Which Type is Best?

- For clothing & textiles: Nylon 6 (softer, more dyeable).

- For industrial uses: Nylon 6,6 (stronger, heat-resistant).

- For medical/automotive: Nylon 12 (flexible, chemical-resistant).

Uses of Nylon

Nylon’s unique combination of strength, elasticity, and resistance to abrasion and chemicals makes it one of the most versatile synthetic materials in the world, especially in the production of apparel .

Its applications span across multiple industries, from everyday consumer products to high-performance industrial and medical uses, including sleeping bags . Below is an expanded look at the key uses of nylon.

1. Fashion & Apparel

Nylon’s lightweight, easy texture, and stretchability make it perfect for apparel. It is typically utilized in:

- Hosiery & Stockings – Nylon replaced silk in stockings due to its sturdiness and affordability.

- Activewear & Swimwear – Its moisture-wicking and brief-drying homes make it ideal for sports clothing, leggings, and swimsuits.

- Outerwear – Windbreakers, raincoats, and light-weight jackets frequently use nylon for water resistance.

- Lingerie & Shapewear – The fabric’s elasticity gives a snug but cushty fit.

2. Outdoor & Sports Gear

Nylon’s high tensile strength and resistance to wear make it vital for outdoor and athletic equipment, including durable materials like tents that dries quickly:

- Tents & Backpacks – Water-resistant and tear-resistant, ideal for tenting equipment.

- Climbing Ropes & Safety Harnesses – Its strength-to-weight ratio guarantees reliability in excessive situations.

- Fishing Nets & Lines – Resistant to saltwater corrosion and abrasion.

- Parachutes & Sails – Lightweight yet durable enough for high-strain applications.

3. Industrial & Automotive Applications

Nylon’s durability and chemical resistance make it valuable in manufacturing:

- Tire Cords & Conveyor Belts – Reinforces rubber products for longevity.

- Fuel Lines & Gears – Resistant to oils and high temperatures.

- 3D Printing Filaments – Used in prototyping due to its flexibility and strength.

4. Medical & Safety Equipment

- Surgical Sutures – Some nylon variants dissolve harmlessly in the body.

- Prosthetics & Orthopedic Implants – Biocompatible grades are used in medical devices.

- Seatbelts & Airbags – Nylon’s shock-absorbing properties enhance vehicle safety.

5. Home & Consumer Goods

Carpets & Upholstery – Resistant to stains and put on.

Toothbrush Bristles – Flexible but durable for daily use.

Musical Instrument Strings – Provides a balance of electricity and elasticity.

Nylon’s adaptability guarantees it remains a widely used fabric across industries, usually evolving with innovations like recycled nylon and bio-based plastic options. Whether in outdoor gear or regular gadgets, nylon’s advantages make it critical.

Environmental Impact of Nylon

Nylon’s durability and versatility come with tremendous environmental results that span its whole lifecycle—from production to disposal, contributing to global warming . As a petrol-based totally artificial plastic polymer, nylon contributes to several ecological demanding situations which are more and more concerning in modern sustainability-focused world.

1. Resource-Intensive Production

Nylon is derived from polymer crude oil, a non-renewable plastic resource, thru an energy-extensive manufacturing process. The manufacturing of sebacic acid and adipic acid, key nylon precursors including various yarns , generates nitrous oxide (N₂O)—a greenhouse fuel 300 instances more potent than CO₂ in using climate exchange. Additionally, nylon production calls for big quantities of water for cooling and processing, contributing to water scarcity in manufacturing regions.

2. Microplastic Pollution

One of nylon’s most pressing environmental issues is microfiber losing, particularly from discarded fishing nets. Every wash of nylon clothing releases hundreds of microplastic fibers into wastewater, eventually accomplishing oceans and freshwater structures. These microplastics:

- Accumulate in marine life, entering the food chain

- Absorb toxic chemicals, becoming more hazardous over time

- Persist for centuries, as nylon doesn’t biodegrade

Studies estimate that synthetic textiles account for 35% of microplastics in marine environments, with nylon being a major contributor.

3. Waste Management Challenges

Nylon’s non-biodegradable nature means discarded products linger in landfills for 30-40 years or more due to the complex manufacturing process . Incineration releases toxic fumes including hydrogen cyanide, while recycling remains limited due to:

- Complex material blends in textile products

- Downcycling (recycled nylon often has inferior properties)

- Low collection rates for post-consumer nylon waste

4. Sustainable Alternatives & Solutions

The industry is actively working to create and develop solutions to mitigate nylon’s environmental impact in daily life:

- Recycled Nylon (ECONYL®): Made from fishing nets and textile waste, reducing virgin plastic use by 50-70%

- Bio-based Nylon: Derived from castor beans or food waste, though still not fully biodegradable

- Closed-Loop Systems: Brands like Patagonia recover and regenerate old nylon products

- Washing Machine Filters: Capture 80-90% of microfibers before they enter waterways

Care and Maintenance of Nylon

Nylon is low-maintenance but requires proper care to extend its lifespan, especially because it dries quickly :

Washing & Drying

- Machine wash cold (prevents melting or warping).

- Use mild detergent (harsh chemicals can degrade fibers).

- Air dry or tumble dry low (high heat can damage elasticity).

Stain Removal

Blot stains immediately (nylon absorbs oils easily).

Avoid bleach (can weaken fibers).

Storage Tips

Store in a cool, dry place to prevent mildew.

Avoid prolonged sunlight exposure (can cause yellowing).

Nylon vs. Other Fabrics

| Fabric | Pros | Cons | Best For |

| Nylon | Strong, elastic, water-resistant | Non-breathable, melts under heat | Activewear, outdoor gear |

| Polyester | UV-resistant, durable | Less stretchy, retains odors | Jackets, upholstery |

| Cotton | Breathable, biodegradable | Absorbs moisture, wrinkles easily | Casual wear, bedding |

| Rayon | Soft, drapes well | Weak when wet, wrinkles easily | Dresses, blouses |

Future of Nylon: Innovations & Sustainability

Researchers are developing:

- Self-healing nylon (repairs small tears automatically).

- Biodegradable nylon (breaks down faster in landfills) and can be molded into various forms.

- Smart nylon fabrics (with embedded sensors for health monitoring).

Conclusion: Should You Use Nylon?

Nylon is an excellent choice for:

✅ High-performance sportswear, nylon clothing & outdoor gear, known for being a strong fabric.

✅ Industrial applications requiring strength & flexibility.

✅ Products needing water resistance & durability.

However, if sustainability is a concern, opt for recycled or bio-based nylon garb.

Final Recommendation:

- For apparel: Choose blends (e.g., nylon-spandex for stretch).

- For heavy-responsibility use: Pure nylon (ropes, commercial fabric).

- For eco-conscious shoppers: Recycled or biodegradable alternatives.

By understanding nylon’s properties, manufacturing method makes use of and environmental effect, you can make knowledgeable choices about its programs for your every day lifestyles.

FAQ About Nylon

Q: Is nylon better than polyester?

A: Nylon is softer and greater stretchy, while polyester is more UV-resistant.

Q: Does nylon shrink in the wash?

A: No, but excessive warmness can melt or deform it.

Q: Can nylon be recycled?

A: Yes, thru specialised programs like ECONYL®.

Q: Is nylon secure for touchy skin?

A: Generally, yes, but a few people may also experience inflammation from artificial fibers.