This material may be used in sportswear, outdoor wear among other apparels because it is breathable, flexible and light in weight. This is because as consumers, designers, and manufacturers seek for materials that offer good performance and are fashionable, mesh stands out. But what exactly is mesh fabric, and why is it so widely used across industries?

In this guide, we’ll cover all the basics about mesh fabric that you should know. This article will explain what mesh is, how it is created, the various types of mesh fabrics, and how it stacks up against other light-weight materials. This article will be useful to you whether you are a fashion designer who sews garments at home, a buyer for a manufacturing company, or a student studying textiles.

What Is Mesh?

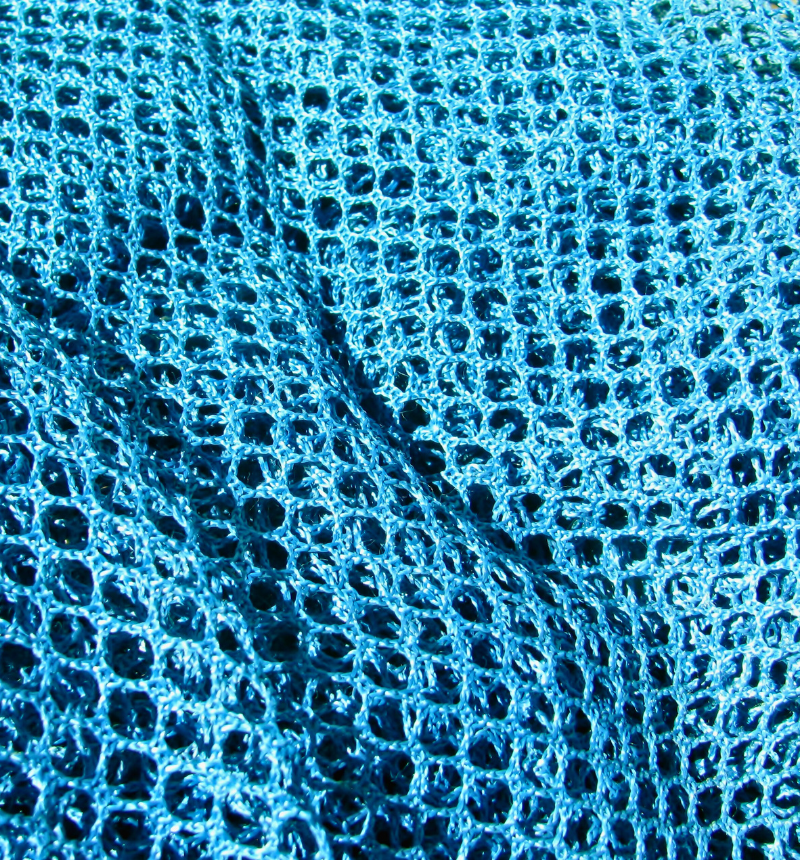

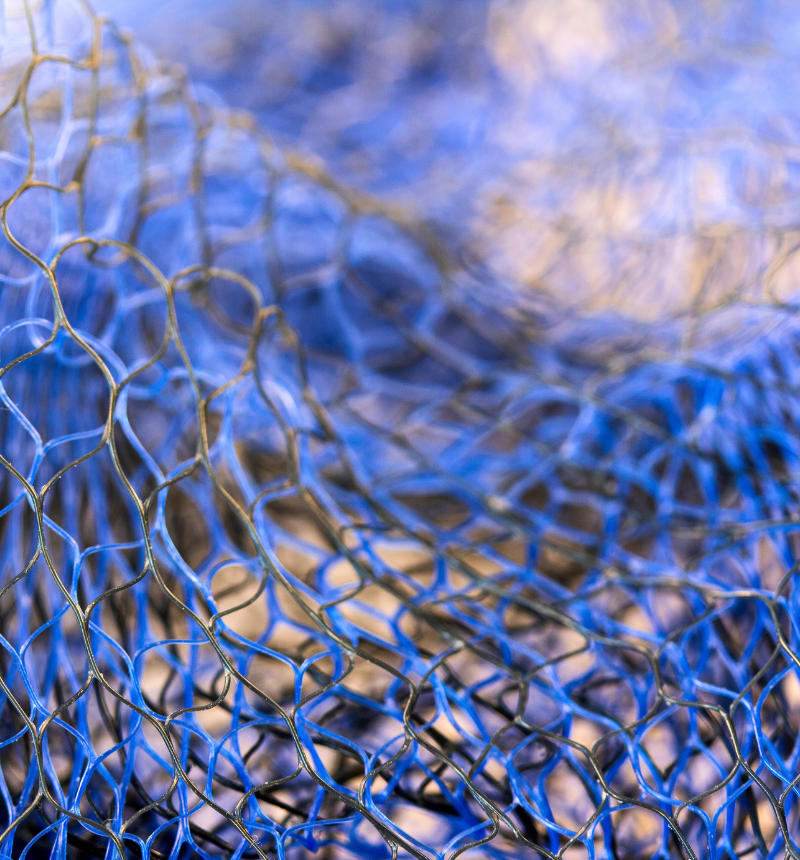

Mesh may also be described as a fabric or structure which has a pattern of interconnecting elements which may be an open hole or a network of interconnecting strands. They are due to breaks or spaces between the threads through which air and moisture can pass through it, thus it is breathable. Mesh is familiar with fabrics, metals, plastics, screens, fences, and even construction equipment.

Mesh is used in fashion and textiles to make wears like sports wears, laundry bags, outdoor furniture and many more. Due to its strength to weight and thermal conductivity it is best suited to products where the material can be as light as possible and flexible while at the same time being porous.

What Is Mesh Fabric?

When we talk of mesh fabric, we are referring to any fabric that has a weft and warp structure with holes in it. These fabrics are made by knitting or weaving synthetic materials such as polyester, nylon, or spandex. These materials offer the mesh fabric strength, flexibility, and processability.

Some of the properties that make mesh fabric famous are:

- Ventilation: This makes a passage through which air can flow, therefore eliminating the buildup of heat.

- Lightweight: Easy to wear or transport

- Flexible: Physical or application gesture or movement

- Fast-drying: Perfect for sports or humid climate areas.

Because of such attributes, mesh is among the most sought-after fabrics by designers and engineers in fashion, sports, and other industries.

How Mesh Fabric Is Made

Mesh fabric can be either knitted or woven, depending on the kind of fabric needed and its strength. Here’s how it works:

Materials Used

- Polyester: Most common. Strong, wrinkle-resistant, and fast-drying.

- Nylon: Lightweight, smooth, and abrasion-resistant.

- Spandex/Elastane: It is used for stretch in athletic or shapewear mesh.

- Cotton blends: For casual fashion wear, especially when it comes to comfort.

Knitted vs. Woven Mesh

- The knitted mesh fabric is delicate and stretchable, and therefore appropriate for fashion and sports wear.

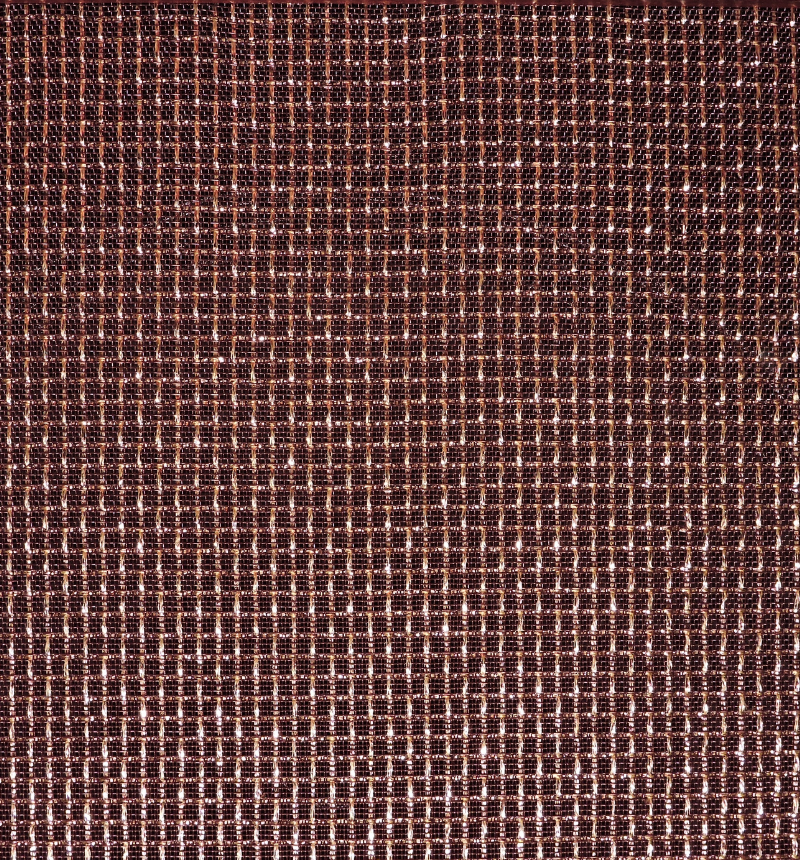

- Warp knitted mesh fabric is denser and more rigid than the weft knitted mesh fabric, and it is used for bags, screen or any other equipment that may be used out door.

- The size of the holes can also vary, ranging from very thin tulle used in wedding veil to wide mesh for basketball jerseys.

Types of Mesh Fabric

Mesh comes in a variety of types, which are developed for a specific purpose for their application. Depending on the type of mesh applied, the layer can be very thin and lightweight or thick and used in industries such as construction and automotive. Let’s take a closer look at the most widespread types of mesh fabric:

1. Power Mesh

Power mesh is described as a light gauge fabric that has stretchability, elasticity, and compressibility qualities. It is commonly used in sportswear, dance wear and shape wear since fit and elasticity are important factors. Power mesh is a kind of fabric which is made from nylon or polyester with spandex and the fabric is very close to the body, elastic and flexible.

It is stiff because of the material used and its construction, but it is not restrictive because it is quite knit. You’ll also find it in supportive panels within the following articles of clothing: sports bras, leggings and compression garments. They are common with brands related to the active outdoor lifestyle and fashion body wear.

2. Tulle Mesh

Tulle is the lightest mesh fabric used in garment construction with a string like structure. This is relatively fine, has a net-like structure, and is often created from nylon, polyester, or silk. Tulle is used for wedding veils, tutus, and elegant gowns because of its sheer appearance. It is relatively weak and is usually employed as a decoration.

Tulle is best for volume and it can be accumulated to the desired density or for the look that is transparent. It is not for daily wear and not for dancing, but formal and fashion wear.

3. Polyester Mesh

Among the many mesh fabrics that are used in the market today, polyester mesh fabric is one of the most famed and durable fabrics. It is also used in producing sport wears like jerseys, bags, washing bags, and working wears. It is easy to use, long-lasting, does not fade, tear or wear out fast and can be used to construct the structure.

Moreover, it affords dye, which makes it suitable for use in products that need to have bright and permanent color. Its most common application is where fabrics are exposed to heavy usage and washing frequently, for example, polyester mesh. It is soft to the touch, lightweight and has absorption properties for moisture, ideal for use in active wear and outer wear lining applications.

4. Nylon Mesh

Nylon mesh is appreciated for its strength, non porous surface and its ability to reduce friction. This material is extensively used in manufacturing of bags, hats, tents, and industrial filters. Nylon fibers are more supple than polyester, and it is more silky in feel; this is another property of great importance, particularly so that an item being produced is likely to be rubbed or exposed to any weather element.

The other special feature is that it is non-slip; it is easy to clean since it does not retain stains and is mildew resistant, and this makes it ideal for use on products that are used outdoors. It can also be coated for more superior strength or for any activity that the material has to be made water resistant.

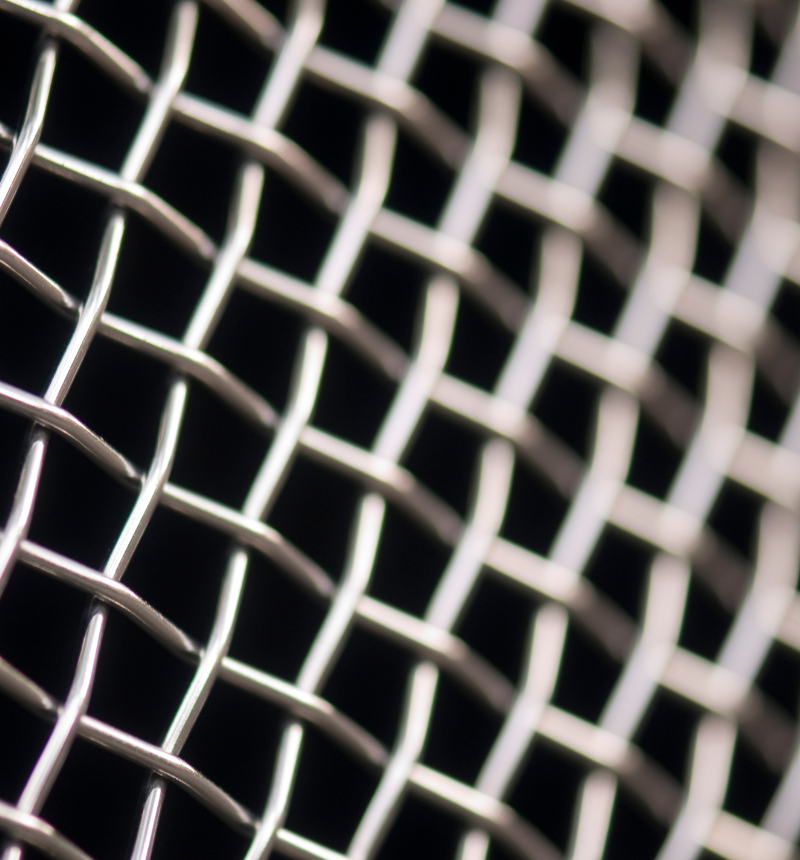

5. Metal Mesh

Metal mesh is not counted as textile material but it has the characteristics of textile structure of fabric woven with interconnecting loops. It is made from steel, aluminum, or copper wire and can be used in filters, security screens, machine guards, and construction reinforcement.

Other fashion designers have also not shied away to use fine metal mesh for the purpose of the new clothing or accessory. This is because metal mesh is strong, heat resistant and it can also be used and be a filter in technical and manufacturing companies.

Common Uses of Mesh Fabric

I think that mesh is actually quite ubiquitous once you pay attention: it is not limited to sportswear only. Due to its light weight and practicality, as well as its strong construction, mesh fabric has numerous use in various common and specific items.

Clothing

The fashion industry displays a strong preference for spacer mesh fabric to create clothing items that need unrestricted flexibility. You’ll find it in:

- Lingerie and underwear: The material both supports the body and lets air pass through while eliminating the need for additional coverings.

- Swimwear lining: The material facilitates easy breathing by helping clothes dry up while providing support.

- Casual fashion tops and dresses: Fashion style emerges from elements layered or sheer in design.

Accessories

Mesh is used in many accessories to help it hold its shape and to create sufficient breathing space. Examples include:

- Mesh panel backpacks: This is due to the fact that it can afford air ventilation, and is relatively lighter than the other types of backpacks.

- Baseball caps: they do cool the heads and are designed to support a structure of their own.

- Belts and gloves: Let fresh air to circulate in active zones of the building.

Outdoor and Travel Gear

It is very durable and dries up very fast, making it ideal for use by the outdoor enthusiasts who will require their gears to work best under extreme weather conditions. You’ll find it in:

- Camping chairs and hammocks: Sturdy to be worn at any season or climate.

- Tent screens and canopies: These are used in windows or walls to provide aeration but will not allow insects to penetrate into the house.

- Utility pouches and travel organizer: For example, it gives visibility and airflow for shaves, knives, and other related tools.

Medical and Industrial Applications

Mesh fabric is not a new concept and is most commonly used in sportswear and accessories, however, it has a lot of uses other than clothing. Due to its ability to breathe, being strong and flexible, mesh has significant uses in the medical and industrial fields. It is in these areas that the emphasis is not on glamour but efficiency, protection and durability.

- Surgical tapes and wound dressings: In medical purposes, mesh fabric is used in surgical tapes, bandages and wound dressings since it creates an environment under which air can circulate on the affected area.

- Face masks and respirators: Mesh layers are used in surgical masks and respirators, particularly in designs that have multiple layers or those that are reusable. The compactness of the mesh is good for capturing larger particles, but let’s air to pass through easily.

- Hernia and soft tissue repair: In more complex surgeries, implantable mesh (from medical grade material) is used in hernia surgery and for reinforcement of tissue. These meshes are lightweight and biocompatible so that they can be safely incorporated into the body tissue or are intended to stay in the body indefinitely.

Pros and Cons of Mesh Fabric

Like any other material, mesh has its own merits and demerits. This knowledge is useful when determining the fabric to choose when designing sportswear, outdoor wear or fashion accessories. Below is a detailed look at what mesh provides and the areas that seem to be lacking:

Pros

- Extremely breathable: This means that since mesh has an open-hole structure, it allows enough exposure to air all the time. This makes it suitable for sunny weather, activities or anything else that may want the wearer to be cooler than the compact weave fabrics allow.

- Lightweight and comfortable to wear: In comparison to solid fabrics, mesh also consumes less materials and therefore is lighter and more pliable. It is suitable for being used in the production of sportswear, travel accessories, or any product that is worn for long and without feeling the weight of the garment, product, or accessory.

- Dries quickly: Polyester, nylon and other synthetic mesh materials have poor fluid absorbent capacity. For the same reason, it is appropriate for use in swimwear, jerseys for sports and any equipment that may be exposed to rain or sweat.

- Durable and tear-resistant: For example, the polyester and nylon mesh made from adipic acid are some of the best when it comes to the issues of durability and wear. It can be used in bags, camping chairs, industrial filters and any product that is likely to be in motion or carry heavy loads.

- Customizable through coatings or blends: It can be coated with water repellent chemicals, UV protective coatings or can be blended with spandex to make stretchable cloth. These boosts allow brands to create mesh fabric to suit a given need; whether it is a waterproof backpack or moisture-wicking undergarment.

Cons

- Low wind and UV protection: It is also weak in holding the wind since the fabric material used in the construction of mesh is weaves. Conversely, it offers little or no protection against UV radiation if not treated properly. For outerwear or clothing that are exposed to sunlight, this can be a disadvantage if not layered or coated.

- Susceptible to snags and tears: While it is very strong and almost tear proof, mesh has a more porous weave and can easily get caught on the edge of an object. Most, especially softer mesh fabrics, run the risk of fraying or tearing when not re-enforced or if they are not hemmed.

- Limited insulation in cold weather: That is the same properties which makes it to be ideal during the hot seasons are the same properties that would make it to be unsuitable during the cold seasons. Mesh is the least insulating and should be used for wear or any gear that is not for insulation during winter.

How to Care for Mesh Fabric

Mesh fabric is very sheer and thin, but if certain guidelines are followed, it’s easy to maintain:

- To prevent snags on the fabric, washing the garment in a laundry bag when using the washing machine is advised.

- To clean, wash on a gentle cycle and in cold water with a mild detergent.

- Low temperature tumble drying is allowed in the event the garment label allows it.

- If the fabric is torn, use fabric glue or sown small tears to repair the fabric.

These tips will assist your mesh garments and gears to be more durable than wearing out their usefulness or elasticity.

Mesh Fabric vs Other Lightweight Materials

| Feature | Mesh Fabric | Cotton | Polyester | Tulle |

| Breathability | Excellent | Good | Moderate | Excellent |

| Durability | High (synthetic mesh) | Moderate | High | Low |

| Stretch | High (knitted mesh) | Low | Moderate | Low |

| Drying Time | Very Fast | Slow | Fast | Fast |

| Best For | Sportswear, gear | Everyday wear | Fast fashion, linings | Decoration, costumes |

Final Thoughts: Why Mesh Fabric Is So Widely Used

Mesh fabric is appreciated based on its performance, comfort and versatility of use. Starting from the fitness center, up to the mountain and even your wedding, mesh is always behind the scenes making sure that things are highly breathable, lightweight and functional. In terms of ventilation, mobility, and design, it’s hard to beat mesh fabric.

As smart textiles become popular among brands, mesh also changes its form with new mixes and coatings, which makes it one of the most popular materials in modern textile industry. If you are selecting fabrics for your next project or want clothing that is lightweight and allows for air circulation, then mesh fabric should be on your list.